How OEM Sand Casting Solves the Rail Industry’s Toughest Component Challenges

Introduction: Why It Matters Now

The rail industry faces unique and demanding challenges in manufacturing high-quality components. From braking systems to motor housings, parts used in rail vehicles must meet stringent mechanical, thermal, and reliability standards. With an increasing demand for efficient, cost-effective production methods, OEM sand casting is rapidly emerging as a preferred solution to address these challenges. But why exactly is this method so effective for the rail industry today? Let’s explore.

Key Challenges in Rail Component Manufacturing

Rail component manufacturers often encounter several challenges in the production process. These challenges, if left unsolved, can lead to increased costs, delayed deliveries, and reduced part quality. Here are some of the most common issues faced:

| Challenge | Impact |

|---|---|

| High Mechanical Stress Requirements | Leads to high-cost materials and machining processes, increasing overall costs. |

| Complex Component Geometry | Increases lead time and machining waste, making it harder to achieve precision. |

| Small to Mid-Volume Runs | Traditional tooling methods are not cost-effective for low-volume or custom orders. |

| Long Lifecycle Parts | Parts require consistent quality and repeatability, making mass production harder to scale. |

What’s at Risk If These Challenges Aren’t Solved

Failing to address these challenges can lead to significant consequences for rail component manufacturers:

Production Delays: Unforeseen delays caused by inaccurate machining or tooling issues.

Safety Risks: Inferior parts that can fail under stress, leading to potential safety hazards.

Increased Maintenance Costs: Parts that wear out too quickly or fail prematurely will drive up maintenance and replacement costs.

Brand Damage: Poor part quality can affect the company’s reputation and relationship with end customers.

Operational Downtime: Disruption of rail services due to component failures or delays in manufacturing processes.

Why OEM Sand Casting is a Game-Changer

OEM sand casting offers a practical and efficient solution to many of these challenges, addressing the specific needs of the rail industry. Here’s how:

| Feature | Benefit for Rail Manufacturers |

|---|---|

| Flexible Molding Process | OEM sand casting easily accommodates complex geometries and part designs, allowing for creative freedom in component shapes. |

| Cost-Effective Tooling | Lower tooling costs make it an ideal solution for small to mid-volume production runs, making it more affordable than traditional casting methods. |

| Material Versatility | Sand casting supports a wide variety of materials, including cast iron, steel, and aluminum, making it adaptable for different rail components. |

| Reduced Lead Times | Faster production cycles help reduce lead times, enabling quicker project delivery and more responsive supply chains. |

Whether it's creating the frame of a railcar, a suspension bracket, or a brake system component, OEM sand casting can meet the rail industry’s demanding standards.

Application Scenarios in the Rail Industry

OEM sand casting service has already proven its worth in the rail industry for the production of numerous key components. Some examples include:

Brake System Components: Brake caliper bases, anchors, and housings.

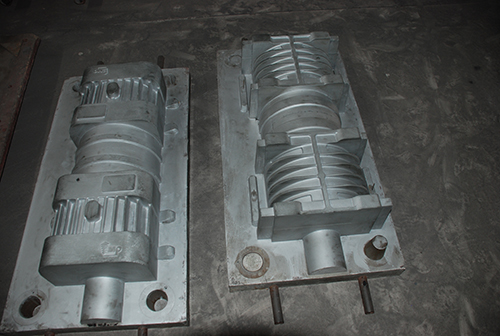

Motor Housings: High-strength castings for traction motors.

Suspension Systems: Complex suspension components such as control arms and mounting brackets.

Signal Equipment: Durable, heat-resistant signal equipment housings and enclosures.

Case Example (Simplified):

A prominent railway manufacturer needed a custom aluminum gearbox housing. Using traditional machining methods, the cost per unit was $85. After switching to OEM sand casting, the cost was reduced to $62 per unit, and lead time was cut by 30%.

Case Snapshot: A Real Rail Project

Here’s a real-world example: A large rail transportation company faced a challenge with producing durable suspension brackets. Their existing supplier used traditional forging methods, which were costly and had high material waste. After switching to OEM sand casting, the company:

Reduced part costs by 20%.

Shortened production lead time by 15%.

Increased part durability and reduced failure rates by 10%.

Conclusion: Should You Consider It?

The rail industry’s need for durable, cost-effective components has never been greater. OEM sand casting offers a smart solution to help manufacturers reduce costs, improve production speed, and meet the high-performance requirements of today’s rail components. If you’re facing challenges in producing high-quality parts efficiently, it might be time to explore this method.

Curious whether OEM sand casting could benefit your rail components? Let’s talk.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0